allows for more economical and faster concept design validation

PLASTIC PART DEVELOPMENT

consists of three main product development stages leading to the final production of the desired plastic component:

YEARS OF EXPERIENCE

in mechanical engineering to develop your product and achieve your real business goals

allows to identify design problems at the early design phase thus decrease the risk of failure

allows to simulate and check more amount of tests by fast and simple modifications in model

allows rapid and cost-efficient design optimization

CAD DESIGN / DFM

Our CAD Design / DfM services for plastic product development help our clients optimize their designs for manufacturability, efficiency, and cost-effectiveness. Our team of experienced engineers and designers use advanced software tools to create 3D models and identify and resolve potential functionality, assembly and feasibility issues early in the design process. This results in faster time-to-market and improved product quality. We work closely with our clients to ensure their product design goals are met while minimizing production costs.

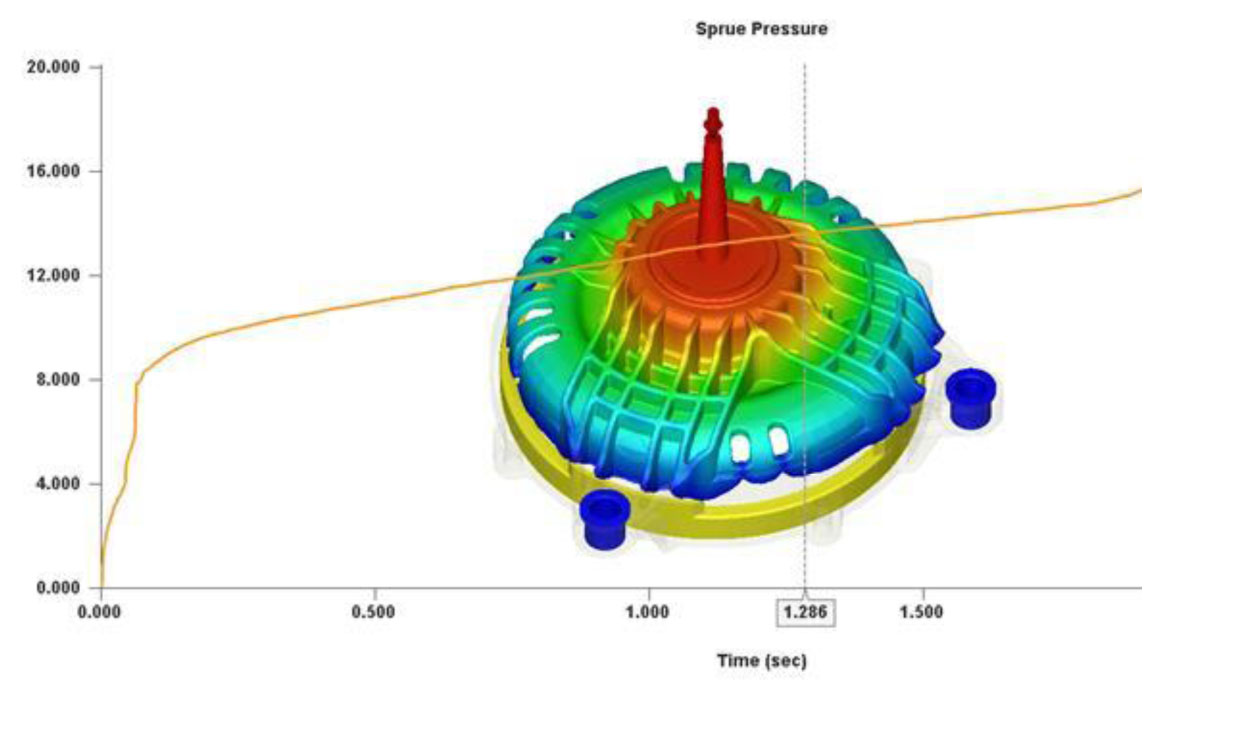

INJECTION MOLDING SIMULATION

Our injection molding simulations for plastic product development provide valuable insight into the manufacturing process, helping our clients optimize their designs for production efficiency and cost-effectiveness. With advanced simulation software, we can predict potential issues and identify areas for improvement early in the design process. This results in faster time-to-market, improved product quality, and reduced costs. Our experienced team works closely with clients to ensure their injection molding needs are met with precision and accuracy.

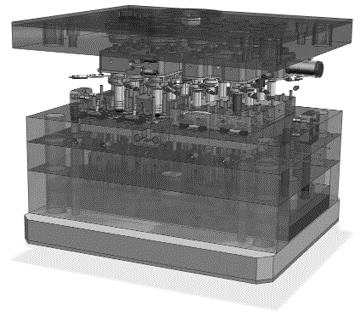

MOLD DESIGN

Our mold design services for plastic product development ensure precise and efficient production of high-quality plastic components. With our expertise in mold design and engineering, we provide tailored solutions that meet specific project needs. Our team uses advanced software tools to create 3D models to identify and address potential issues early in the design process. This results in faster time-to-market, improved product quality, and reduced production costs.

Pre-Sale Questions

Prospective functionalities for interactive commun generate economically sound infrastructures before process.