allows for more economical and faster concept design validation

VIRTUAL DEVELOPMENT of TURBOCHARGERS and eCOMPRESSORS

is an integral part of product development for the following reasons:

over 20 YEARS OF EXPERIENCE

in mechanical engineering to develop your product and achieve your real business goals

allows to identify design problems at the early design phase thus decrease the risk of failure

allows to simulate and check more amount of tests by fast and simple modifications in model

allows rapid and cost-efficient design optimization

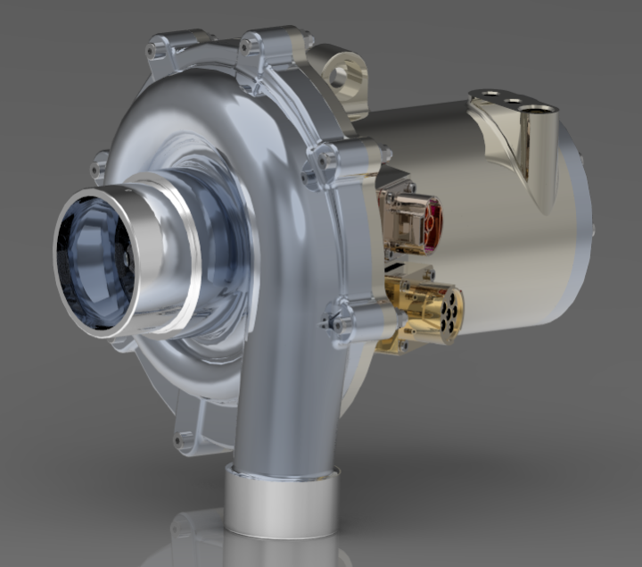

TURBOCHARGER DEVELOPMENT

we specialize in turbochargers designed to revolutionize various industries. These innovative devices offer unparalleled performance and efficiency.

- Electrical Turbochargers: Driven by electric motors, our turbochargers provide precise control and energy efficiency. From automotive applications to marine vessels, our electrical turbochargers enhance power output.

- Water-Cooled Turbocharger and Manifold: Our turbochargers incorporate advanced water cooling technology, ensuring optimal performance even under extreme conditions

- Various scroll types: The development of turbochargers, featuring various scroll types such as Single Scroll, Twin-Scroll, Segmented Scroll, Radial Scroll, and Mixed-Flow Scroll, empowers you to choose the optimal scroll technology for your application. These advancements enhance performance, reduce turbo lag, and optimize power delivery.

- Turbocharger control mechanisms: These technologies like Wastegate Actuator, VTG (Variable Turbine Geometry) Actuator, Wastegate Control, Two-Stage Turbochargers

enhance performance, reduce lag, and optimize power delivery. - Virtual simulations: for Enhanced Performance like Aero 1D+3D Simulations, Rotor Dynamic Analysis, CFD Simulations, TMF Analysis, Thermal simulations, Strength Simulations play a vital role in engineering, research, and development across various industries.

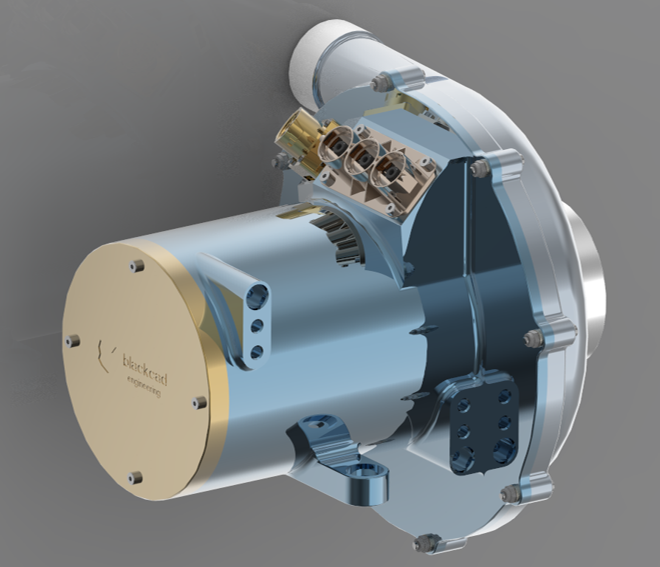

eCOMPRESSOR DEVELOPMENT

we specialize in cutting-edge eCompressors designed to revolutionize various industries. These innovative devices offer unparalleled performance and efficiency.

- Fuel Cells: Our eCompressors play a vital role in fuel cell systems, ensuring efficient gas compression for power generation and transportation. Whether it’s powering electric vehicles or supporting stationary fuel cells, our eCompressors deliver reliability and performance.

- Oil-Free Bearings: We take pride in our advanced eCompressors that utilize oil-free bearings. By minimizing friction and enhancing reliability, these compressors are ideal for hydrogen applications. Trust in our technology for clean and efficient energy solutions.

- Electrical Drivers: Our eCompressors are driven by electric motors, offering precise control and energy efficiency. Whether you’re in the automotive, industrial, or renewable energy sector, our eCompressors provide the power you need.

- Cooling Applications: eCompressors are integral in cooling systems, maintaining optimal temperatures under various loads. From industrial processes to data centers, our eCompressors ensure efficient cooling performance.

- Inverters: Seamlessly integrating into energy systems, our eCompressors incorporate state-of-the-art inverters. Experience enhanced performance and adaptability with our innovative solutions.

APPLICATIONS

Applications of Turbochargers and eCompressors

- Cooling and Refrigeration Systems: Turbochargers and eCompressors play a crucial role in enhancing the efficiency of cooling and refrigeration systems, ensuring optimal performance.

- Transportation:

- Automotive: Turbochargers and eCompressors are integral components in modern automotive engines, boosting power and improving fuel efficiency.

- Aviation: These technologies enhance aircraft engine performance, enabling better altitude capabilities and fuel economy.

- Marine: Turbochargers and eCompressors contribute to marine propulsion systems, increasing power output and reducing emissions.

- Rail: In locomotives, they enhance engine efficiency and reduce environmental impact.

- Thermal Power Plants: Turbochargers and eCompressors are employed in power generation plants to optimize combustion efficiency, leading to higher energy output.

- Waste Heat Recovery: These systems recover energy from exhaust gases, converting waste heat into usable power, benefiting industries and reducing environmental impact.

- Energy – Distributed and Renewable: Turbochargers and eCompressors support distributed energy systems, including renewable sources like wind and solar, by improving energy conversion efficiency.

- Fuel Cells: These technologies enhance fuel cell performance, ensuring efficient energy production in various applications.

Pre-Sale Questions

Prospective functionalities for interactive commun generate economically sound infrastructures before process.